Mini lean concrete plant

Fixed position mixing bucket

Mini plant for high-yield stabilized and lean concrete

The stabilized and lean concrete plant uses the unique mixing system of Warzée mixing buckets. Fully automated, it allows for the quick production of stabilized materials or lean concrete.

Consisting of a fixed mixing bucket, the plant is fully customizable with the addition of various elements: waiting hopper, conveyor belt, silo, etc.

The most

- Paddle mixing system

- High-efficiency automated system

- Fully modular

The machine in action

Configure your Mini lean concrete plant

Any questions ?

Features

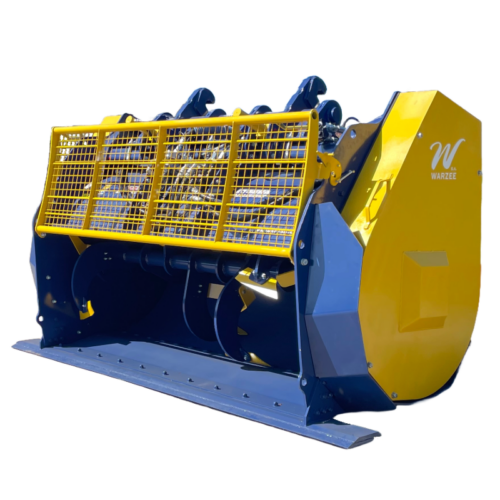

Unchanged mixing system

The stabilized and lean concrete plant is equipped with a fixed-position mixing bucket (1500 liters).

The bladed mixing system guarantees quick and homogenous mixing with an output capacity of 45 m³/h.

Mix registration and management from a tablet

An application installed on a tablet (provided with the plant) allows you to preset the amount of cement and water, as well as the mixing time for each batch. It also enables you to start the mixing process or activate the conveyor belt. Thanks to the tablet, these actions can be performed remotely, particularly from the loading machine.

Aggregate input

The concrete mixing plant is linked directly to a cement silo. Cement and water are added automatically.

The operator only must put the aggregates (e.g. sand) into the hopper and start the mixer.

The hopper

The hopper, positioned above the mixer bucket, enables the operator to gain time as he is able to prepare the following mix.

The hopper is equipped with a weighing system for measuring the quantities of aggregates (sand, gravel, etc.) instantaneously.

Conveyor belt

Once mixing is finished, emptying takes place through the mixer bucket’s central sliding shutter.

The conveyor belt enables the mix to be loaded at different heights (trailers, hoppers, etc.).

Hydraulic system

The mixer bucket drive and the other different functions are carried out hydraulically.

Hardox in My Body ™

The mixer bucket body is made using Hardox ® steel.

This hard wearing steel is particularly resistant to abrasive mixes. All the bucket mixers have the Hardox in My Body ™ guarantee.

Replaceable base

All the Warzée mixer buckets are designed to receive a bolt-on replaceable base.

The replaceable base increases the working life of buckets that are already renowned for their toughness.

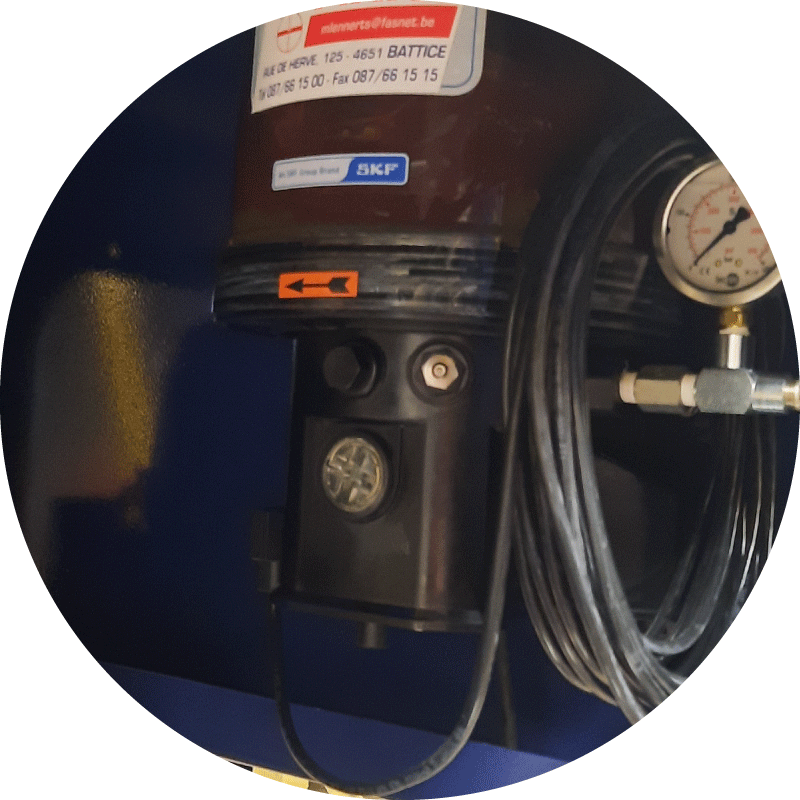

Centralized lubricator

This option automatically lubricates the various lubrication points throughout the system.

Available options

Hydraulic power pack

The hydraulic power pack ensures rotation of the mixer and operation of the various cylinders equipping the plant.

Control cabinet with Automation + Tablet

The tablet is used to program the various mixing recipes and control the plant’s components. The PLC integrated in the cabinet automatically manages the water and cement supply.

Hopper

The waiting hopper is used to prepare the next mix.

Cement silo

The cement silo is used to store cement for supply to the plant.

Cement screw

The cement screw conveys cement from the silo to the plant.

Distribution screw

The distribution screw distributes cement evenly throughout the mixer, reducing mixing times.