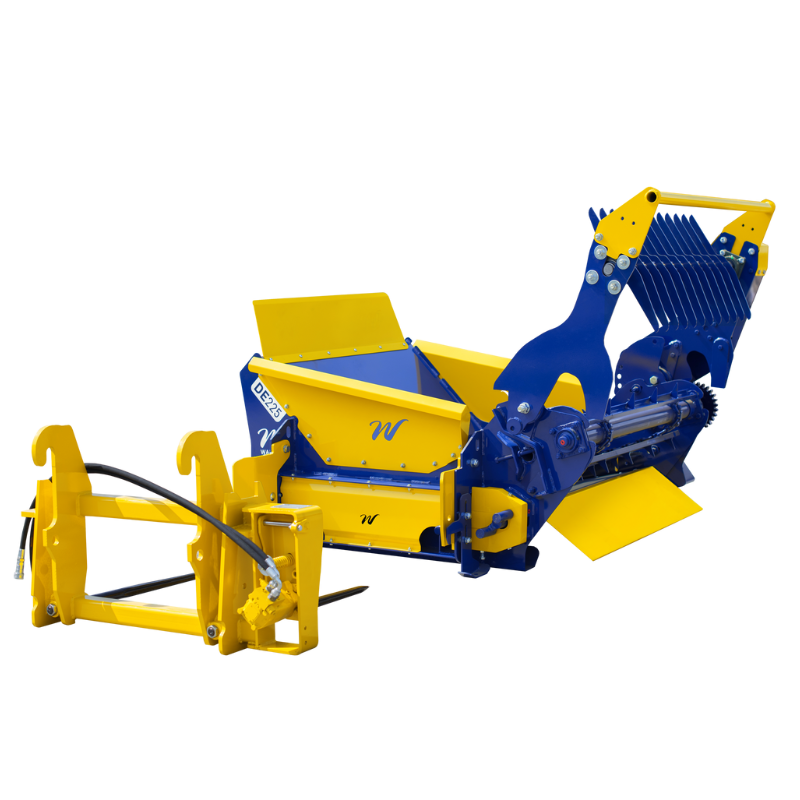

DE225 unroller

Compact round bale unroller

Suitable for compact and mini farm handlers

Specially designed for compact loaders and mini farm handlers, the Warzée DE225 distributes round bales of forage, hay and wrapped silage of up to 150 cm and 800 kg. The machine is made up of a back plate with bale spikes and a narrow and lightweight distribution body. Fitted with a straw spreading kit (option), the machine is also capable of spreading round bales of straw.

The most

- Automatic hitching

- Reduced overhang and weight

- Two-way distribution conveyor

- Only one hydraulic service is required

- Mechanical straw spreading kit (Option)

The machine in action

Configure your DE225 unroller

Any questions ?

Features

Quick hitching

The unroller includes a back plate fitted with bale spikes. The back plate enables the bale to be loaded, and the machine to be hitched and driven without the need for the operator to intervene manually.

Hitching the two bodies mechanically is 100% automatic.

Reduced overhang

The weight and the width of the unroller are reduced in order for it to be ideally suited for use with compact handlers.

Hitching is offset to the right of the unroller in order to reduce the overhang of the distribution body.

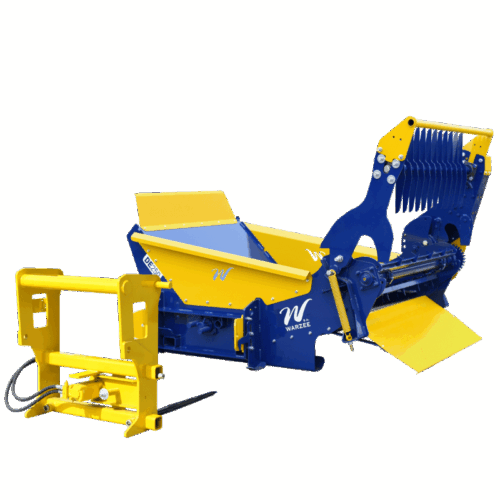

A multipurpose machine

The unroller is capable of distributing all types of round bale: forage, hay, wrapped silage, haylage, straw, etc.

The conveyor’s ability to revolve in both directions enables damp or compact bales to be distributed.

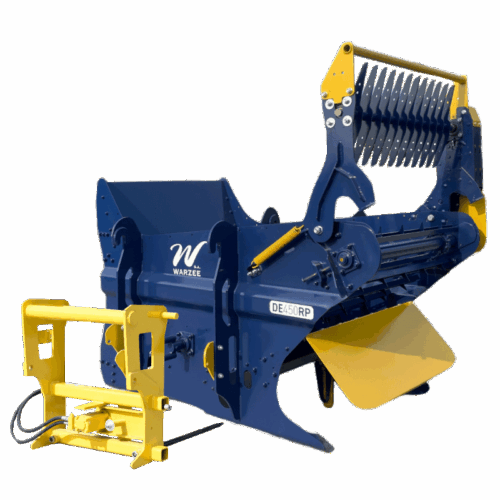

Straw spreading kit

Each Warzée unroller can be fitted with a mechanical straw spreading kit.

The straw spreading kit does not require any extra hydraulic couplings and it enables straw to be spread up to 7 metres whilst keeping dust levels to a minimum.

Fully customizable

Not only is there the straw spreading kit, but there are also numerous options available that will enable you to create a machine to suit your needs.

Optimised unroller support

As soon as the unroller is lifted, the safety locking catches become secured.

They attach the body to the back plate in order to allow for the different situations that may occur (long distances, sharp breaking, etc.).

Distribution to the left, to the right and frontal

The machine can be equipped with a second distribution side and/or frontal distribution (options).

The unroller simply has to be hitched to the opposite side in order to change the unrolling direction (left/right/frontal).

For compact handlers

The unroller can be adapted to fit the majority of small handlers: mini handlers, compact handlers, etc.

The back plate with bale spikes is made-to-measure, with suitable brackets fitted.

Available options

Bottom plate

The floor is to be found under the conveyor belt. It enables all of the material to be kept in the unroller and eliminates any losses.

Extension plate

The extension enables the hay and straw being handled to be held in the chamber. It is strongly advised for bales of more than 1.30 m in diameter, the extension stops the material from being lost.

Side plates (1 or 2)

The sides can be put on both sides of the unroller. They enable the bale to be kept in the unroller’s chamber and likewise eliminate any losses.

Both sides distribution (2nd side)

A second side enables distribution to be carried out from both the left and right-hand sides. The automatic hitch enables the change from one side to the other.

Front Distribution (3rd Side)

A third hooking point can be added to the machine, allowing distribution and mulching from the front, in addition to the two other sides.

Swivel Wheels

The addition of 2 swivel wheels allows the unwinder to be used with loaders with a low lifting capacity (from 500 to 1500kg). However, this option limits the use of the machine to one side only.

Straw spreader kit

Mechanical deflector

Specifications

| Type de distribution | |

|---|---|

| Distribution de balles | |

| Type de paillage | ✗ |

| Paillage de balles | |

| Distance de paillage | ✗ |

| Poids ballot | |

| Accrochage / Tablier pique-bottes | |

| Nombre de côtés d'accrochage | 1, 2 or 3 |

| Verrouillage de sécurité | ✓ |

| Moteur hydraulique | ✓ |

| Largeur rotor | |

| Hauteur rotor haut | 112 cm |

| Capacité de levage / Chargeur | |

| Poids | |

| Transmission | Double effect |

| Débit d’huile | Min. 30 L/min |

| Pression | Max. 170 bar |