DE450R unroller

Round bale unroller

Tough and efficient

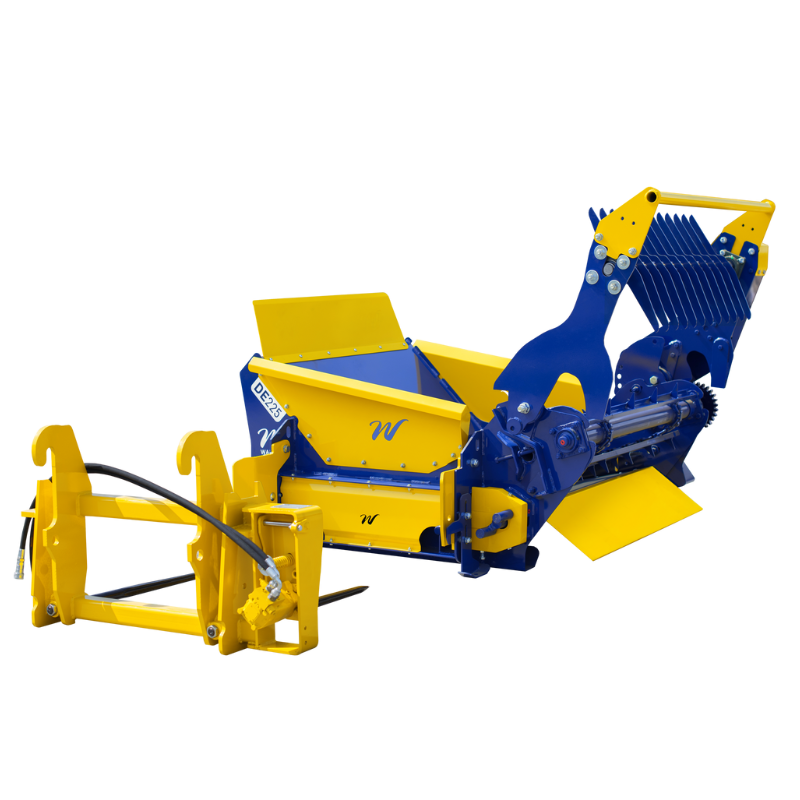

Renowned for nearly 30 years, the Warzée DE450 bale unroller is now the DE450R. It features a bale spike frame and a high distribution box, capable of handling round hay and wrapped silage bales up to 1200 kg.

The most

- Automatic hitching

- Complete body

- Two-way conveyor

- Only one hydraulic service required

Configure your DE450R unroller

Any questions ?

Features

A multipurpose machine

The unroller is capable of distributing all types of round bale: forage, hay, wrapped silage, haylage, straw, etc.

The conveyor’s ability to revolve in both directions enables damp or compact bales to be distributed.

Quick hitch

The unroller includes a back plate fitted with bale spikes. The back plate enables the bale to be loaded, and the machine to be hitched and driven without the need for the operator to intervene manually.

Hitching the two bodies mechanically is 100% automatic.

Optimum support for the unroller

As soon as the unroller is lifted, the upper tube on the back plate fits into the unroller’s hooks.

These attach the body to the back plate in order to allow for the different situations that may occur (long distances, sharp breaking, etc.).

Tall design

The unroller has a tall body, which is particularly useful when trying to avoid wastage when using very big, deformed, or poor quality bales.

Distribution to the left, to the right and frontal

The machine is equipped for distribution in two directions (left/right). The unroller simply has to be hitched on the opposite side in order to change the unrolling direction.

The unroller can also be equipped in order to enable frontal distribution (option).

For telescopics and front end loaders

The unroller is especially suitable for all-terrain telescopic handlers and front end loaders.

The back plate with bale spikes is made-to-measure, with suitable brackets fitted.

Available options

Extension Plate

The extension plate helps keep straw or feed in the box. Recommended for bales larger than 1.60 meters in diameter, the plate prevents any loss of material.

Frontal distribution (3rd side)

In addition to the second side distribution, a third side can be mounted on the machine. This option enables frontal distribution and bedding.

Belt Extension

The belt extension increases the lateral offset of the machine, which facilitates the distribution of feed into troughs.

Easycut

An innovative knife designed to easily and efficiently cut nets, plastics, and ropes, providing ideal versatility.

Specifications

| Feeding type | |

|---|---|

| Feeding bales | |

| Bedding type | ✗ |

| Bedding bales | |

| Bedding distance | ✗ |

| Bale weight | |

| Number of sides | 2 or 3 |

| Locking catches | ✓ |

| Hydraulic motor | ✓ |

| Rotor width | |

| High rotor height | 147 cm |

| Lifting capacity / Loader | |

| Composition | |

| Trough discharge | |

| Weight | |

| Transmission | Double effect |

| Oil flow | Min. 30 L/min |

| Pressure | Max. 200 bar |