Mixers

Filters

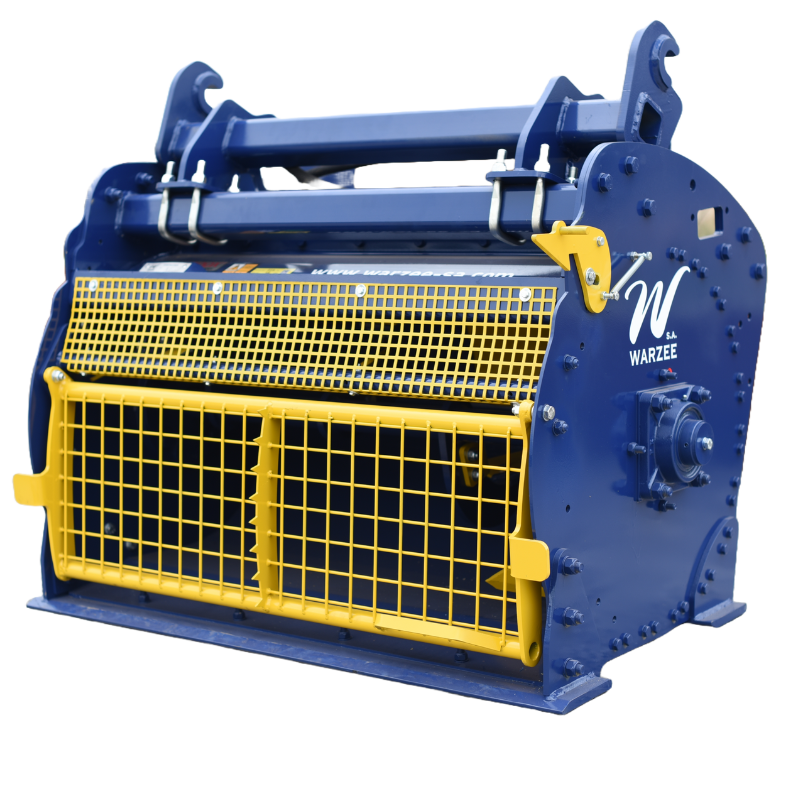

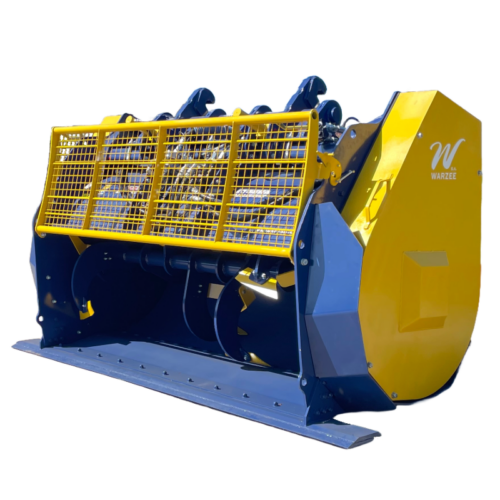

Description

Discover our complete range of mixing buckets designed to meet the needs of professionals, offering capacities suitable for all types of machines.

Warzée’s mixing buckets are engineered to handle various on-site requirements. They ensure efficient mixing of materials such as concrete, gravel, or other mixtures essential for your work. These accessories are highly versatile and perfectly suited for use on construction sites, agricultural operations, or industrial projects. Their robustness and smart design make them particularly ideal for intensive tasks.

Discover Our Range of Civil Engineering Machines

Sweepers

Optimize cleaning with our sweepers, specially designed to efficiently collect all types of ground debris.

Silos

For cement storage and dosing or handling powdery materials, our construction silos offer reliable and practical solutions.

Buckets

The Warzée trap bucket features a smart bottom-opening system, ideal for filling bulk bags with aggregates.

Automatic Hydraulic Connectors

Simplify operations with our automatic connector for quick, reliable, and secure equipment coupling.

Why choose a Warzée mixing bucket?

Capacity

Available in various sizes, from 150 to 2000 liters.

Versatility

Designed to fit different types of loaders and telescopic handlers. Custom bolt-on attachments ensure perfect compatibility with your equipment.

Robustness

Made with Hardox® steel, renowned for its superior durability. The protective grid ensures safe mixing even under extreme conditions.

Speed

A Warzée mixing bucket delivers a perfectly homogeneous mix in just one minute.

Durability

Each Warzée mixing bucket features an interchangeable bolt-on bottom, significantly extending the product’s lifespan.

Accessories

Each mixing bucket can be equipped with a wide range of options to perfectly adapt to any work situation.

FAQ – Everything you need to know about our mixing buckets

What is a mixing bucket, and why use it?

A mixing bucket is an essential hydraulic attachment for efficiently mixing materials. Versatile and durable, it improves mixing operations while optimizing the productivity of your machines.

What types of materials can it mix?

You can load and mix various aggregates, including cement, concrete, stabilized materials, soil, lime, gravel, pebbles, wood chips, sand, and clay. The paddle mixing system ensures a homogeneous blend of both dry and wet materials, regardless of granule size.

What is the screening option?

Our mixing buckets can be equipped with a removable screening grid that fits our entire range. This innovation combines two functionalities in one piece of equipment:

- Classic mixing for materials such as concrete, stabilized mixes, rammed earth, lime-treated soil, or emulsion gravel.

- Screening construction debris to sort and reuse materials, promoting sustainable resource management while optimizing your operations.

What is Hardox in My Body™?

Warzée mixing buckets are made from Hardox® steel, known for exceptional wear resistance.

Perfect for abrasive mixtures, this steel ensures optimal durability. All our buckets carry the Hardox in My Body™ quality label.

How to choose the right mixing bucket?

Use our online filter to find the ideal mixing bucket for your equipment. Compare technical specifications, including capacity, weight, and width. For further guidance, contact us for expert advice.

Why choose Warzée mixing buckets?

Opting for Warzée mixing buckets means choosing proven expertise and high-quality Belgian design. Fully customizable to meet your specific needs, our products offer tailored options for capacity, width, and additional accessories. Our dedicated customer service team supports you throughout the purchasing process and provides reliable after-sales assistance to ensure your complete satisfaction.

How to buy a Warzée mixing bucket?

Request a quote directly from our website or contact one of our authorized dealers. We guarantee fast and efficient worldwide delivery, including Belgium and France.

Where are Warzée mixing buckets manufactured?

All our mixing buckets are designed and built in Belgium at our Hamois facility. This full control from design to after-sales service ensures top-quality machines tailored to the specific needs of our customers.