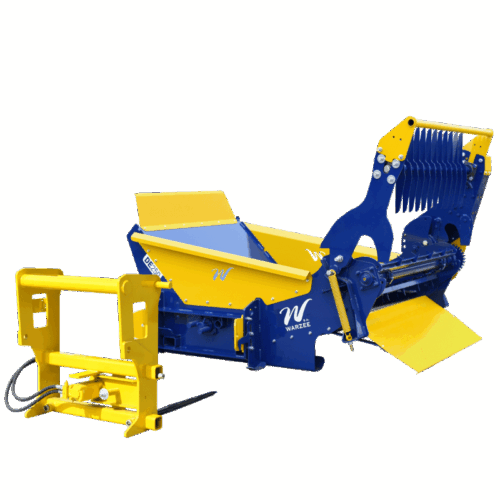

DE500 unroller – straw spreader

Round bale unroller and round and square bale straw blower

One machine for feeding and bedding

The Warzée DE500 unroller-spreader enables any round bale of hay or silage to be distributed. Versatile, this machine can also be used for bedding both round and square bales up to 15 meters.

More ergonomic, the Warzée DE500 is free of any electrical function and equipped with a ” Switch ” hydraulic inverter to automatically switch between feeding and bedding.

The most

- Automatic hitching

- ” Switch ” hydraulic inverter

- Suitable for both round and big square bales

- Less dust

- Spreads straw up to 15 m

The machine in action

Configure your DE500 unroller – straw spreader

Any questions ?

Features

Unroller ...

Once the rotor has been raised, the machine can unroll round bales of hay and wrapped silage.

The conveyor’s ability to revolve in both directions enables damp or compact bales to be processed.

... straw spreader!

When the rotor is lowered, the machine switches into straw spreading mode, and is capable of handling both round and big square bales.

By using the hydraulic deflector, the operator can alter the straw spreading distance from 2 to 15 m.

Quick hitching

The machine includes a back plate fitted with bale spikes. The back plate enables the bale to be loaded, and the machine to be hitched and driven without the need for the operator to intervene manually.

Hitching the two bodies mechanically is 100% automatic.

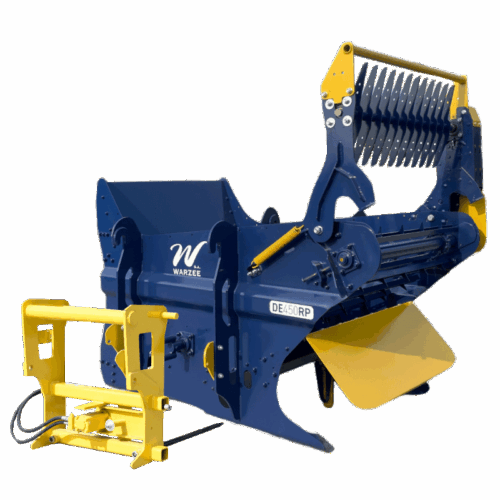

" Switch " system

Simply place the machine on the ground to alternate functions and switch from distribution to straw spreading in seconds.

Thanks to this unique system, the machine is free of any electrical function and does not require any additional hydraulic function on the telescopic handler!

Rotor

The straw spreading rotor is the opposite to the traditional turbines.

It is specially designed to eliminate blockages, to conserve the straw’s stalk length, whilst limiting the amount of dust produced.

Deflector

The straw spreading rotor is equipped with a mechanical deflector.

By manually adjusting it, the operator can adjust the bedding distance, for long straw areas or narrower boxes.

Distribution to the left, to the right and ahead

The machine is equipped for distribution in two directions (left/right). The unroller simply has to be hitched on the opposite side in order to change the unrolling direction.

The straw processor can be equipped for frontal hitching (option).

Suitable for all telescopic handlers

The straw processor can be fitted to any type of telescopic handler (Merlo, Manitou, JCB, New Holland, Dieci, Massey Ferguson, etc.).

The back plate with bale spikes is made-to-measure, with suitable brackets fitted.

Available options

Frontal distribution (3rd side)

In addition to the second side distribution, a third side can be mounted on the machine. This option enables frontal distribution and bedding.

Easycut

An innovative knife designed to easily and efficiently cut nets, plastics, and ropes, providing ideal versatility.

Specifications

| Type de distribution | |

|---|---|

| Distribution de balles | |

| Type de paillage | Hydraulic rotor |

| Paillage de balles | |

| Distance de paillage | 1 to 15 m |

| Poids ballot | |

| Accrochage / Tablier pique-bottes | |

| Nombre de côtés d'accrochage | 2 or 3 |

| Verrouillage de sécurité | ✓ |

| Moteur hydraulique | ✓ |

| Largeur rotor | |

| Hauteur rotor haut | 240 cm |

| Capacité de levage / Chargeur | |

| Poids | |

| Transmission | Double effect |

| Débit d’huile | Min. 85 L/min |

| Pression | Max. 200 bar |